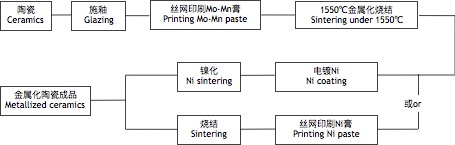

Because the surface structures of metal and ceramic are totally different, it is impossible to weld metal and ceramic together directly. Therefore, we have used a special technique to weld them together which is called metallization. We first make a metallization level stick to ceramic surface which works as a transition layer. Then metal and ceramic can be welded together. This technique is the key to weld metal and ceramic. The metallization level can be obtained by sintering Mo-Mn paste on ceramic surface under high temperature of 1550 Celsius degree.

Application | Typical products |

Electrical power | Vacuum Interrupter |

Electronic | X-Ray tubes |

Energy resources | Microwave tubes |

Mechanism | Electronic tubes |

Medicine & Chemical industry | Insulating parts |

Nuclear power | |

Aerospace |

Technical indicators

Metallization level thickness: 17-22μm

Nickel level thickness: 4-7μm(Ni coating);7±1μm(Ni sintering)

Average tensile strength: 2500Kgf/cm2

Metallization process

Previous:Vacuum Switch introduction

Next:Our business scope

|

Address |

|

Lantian Village, Xianghu Town,Fuliang County,Jingdezhen City,Jiangxi Province,China |

|

TEL |

|

+86-798-2665333 +86-798-2661241 +86-798-2665473 |

|

|

|

FAX |

|

+86-798-2661370 |

|

Online Consultation |

|

CLICK HERE |